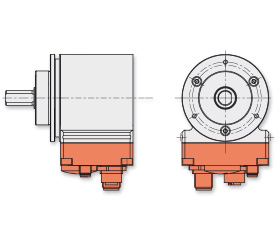

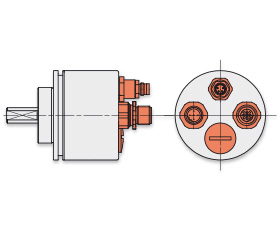

Connectivity for Absolute Angular Displacement Transducers

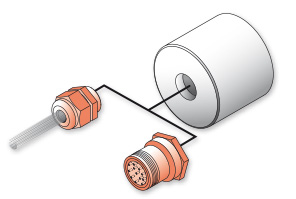

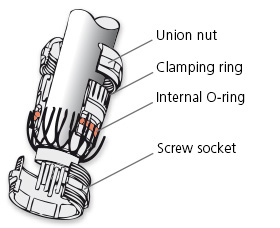

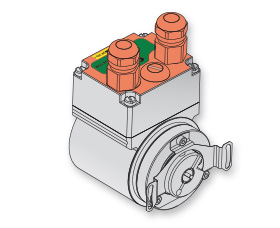

The absolute angular displacement transducers from TR can be supplied with various plugs or cable glands. It is advisable to use a plug if the wiring and assembly of the angular displacement transducer are to be performed at different times or if the transducer has to be replaced quickly and easily. On the encoder side, you will normally find a flanged plug (pins); to connect this, you will need a coupling or cable socket into which to plug the cable or control unit. Specifications and details of plug types are available on request.