Safety-Certified Encoders in Machine Safety

Safety-Certified Encoders in Machine Safety

Modern production lines and industrial machines must meet high standards not only for efficiency but also for safety. At this point, the control, state, and accurate detection of the position of moving parts become critical for human safety and process integrity.

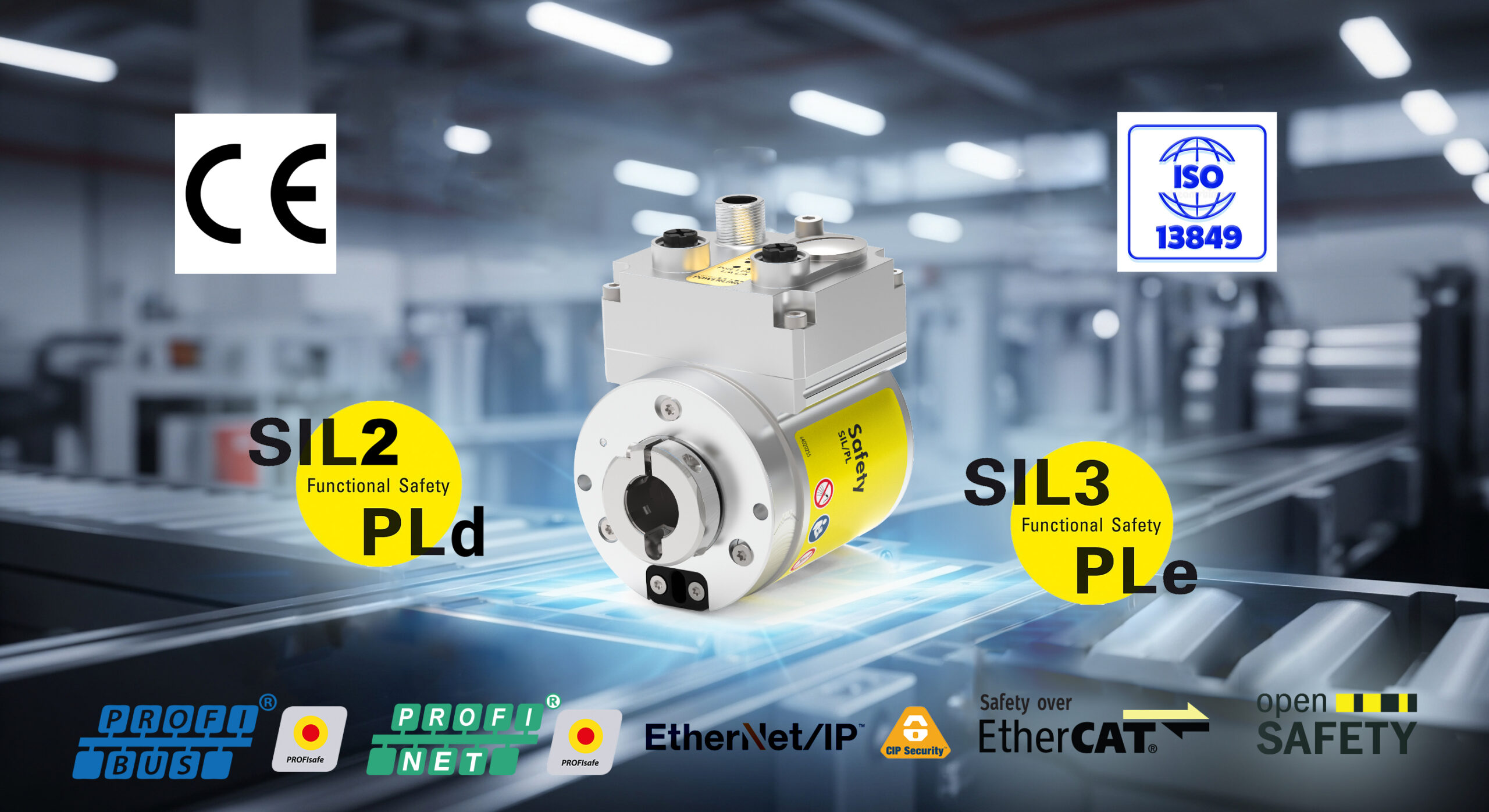

This is exactly where safety-certified encoders become an integral component of machine safety systems. In this article, we detail the encoder’s role in safety systems within the context of international standards such as CE, SIL, PL, EN ISO 13849.

What Is the Encoder’s Primary Role in Safety Systems?

Encoders report the position, speed, and direction of moving parts to the control system, making machine operation observable and controllable. In safety scenarios, this data enables:

- Early detection of hazardous motion

- Triggering of emergency stop (E-Stop) algorithms

- Serving as the basis for functions such as safe speed, safe direction, and safe stop

Safety encoders can detect not only position but also defined fault conditions (e.g., cable break, magnetic interference, signal synchronization error).

What Are CE, SIL, PL, and EN ISO 13849?

✅ CE Marking (Conformité Européenne)

- Legally required for machines to be sold in the European Economic Area.

- The CE mark indicates that the product meets essential safety and environmental standards.

- Compliance with standards such as EN ISO 13849 is required for CE.

✅ SIL (Safety Integrity Level) – IEC 61508 / IEC 62061

- A risk-reduction level indicating how safely a system operates.

- Levels range from SIL1 to SIL4 (SIL4 is the highest).

- Safety encoders are typically certified to SIL2 or SIL3.

- Commonly used in automotive, packaging, textile, and press machines.

✅ PL (Performance Level) – EN ISO 13849

- Primarily used for machine safety.

- Five levels exist from PL a (lowest) to PL e (highest).

- Encoders at PL e are used in systems for safe position and speed monitoring.

✅ EN ISO 13849

- One of the most important standards for machine builders.

- Evaluates the safety functions of control systems.

- Determines the conformity of all components used in functions such as safe braking, guard locking, and speed monitoring.

How Do Safety Encoders Make a Difference?

Safety encoders from TR Electronic, our distributed brand, are certified to SIL2/SIL3 and PL d/e levels. These encoders:

- Ensure signal integrity with a dual-channel output

- Provide a redundant architecture for safe response under fault conditions

- Keep the system under continuous control via built-in diagnostics

- Are ready for use directly in EN ISO 13849-compliant applications

Real Application Examples

- Eccentric presses: ensuring the die does not move beyond the safe zone

- Automatic doors: preventing human contact using position feedback

- AGVs and autonomous robots: applying safe speed limitation

Key Points When Selecting an Encoder for a Safety System

| Criterion | What to Consider |

|---|---|

| Certification | SIL2/SIL3, PL d/e |

| Output type | Redundant (dual) output |

| Interface | PROFIsafe, FSoE, CANopen Safety |

| IP protection class | IP65–IP69K (depending on environment) |

| Diagnostics & fault reporting | Integrated in-system fault reporting |

Conclusion

Today, machine safety is not optional; it is mandatory. Safety-certified encoders have become components that directly impact the safety of people and systems on your production line, not just devices for position measurement.

TR Electronic safety encoder solutions we distribute are developed with high-quality German engineering and meet CE, SIL, and PL requirements.