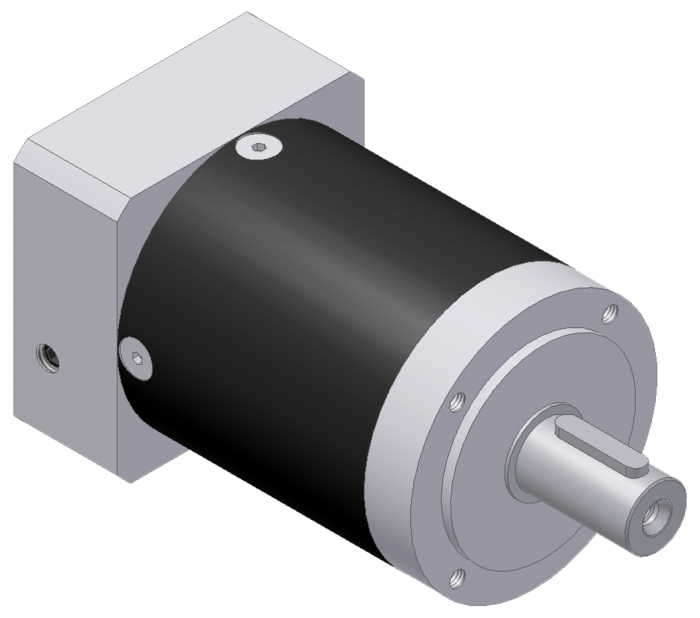

Planetary Gear PLE 80 – Permanent Operation / Periodic Duty up to 130 / 208 Nm

The PLE 80 is the perfect economical alternative to servo planetary gears. The motor and gear are connected with a detachable coupling and clamping hub. Friction losses cannot be neglected. The gear is suitable for all applications where it is adequate to have a backlash of approximately 15 arcmin.

Features

- 22 different gear ratios, i = (3 … 512)

- low backlash (9-14-16 arcmin), (1-2-3)-stage

- high level of efficiency (96-94-90 %), (1-2-3)-stage

- high admissable shaft forces, 1.200 … 950 N, axial-radial

- coaxial shaft output

- high short term overload factor 1,60

- arbitrary mounting position

- lifetime lubrication

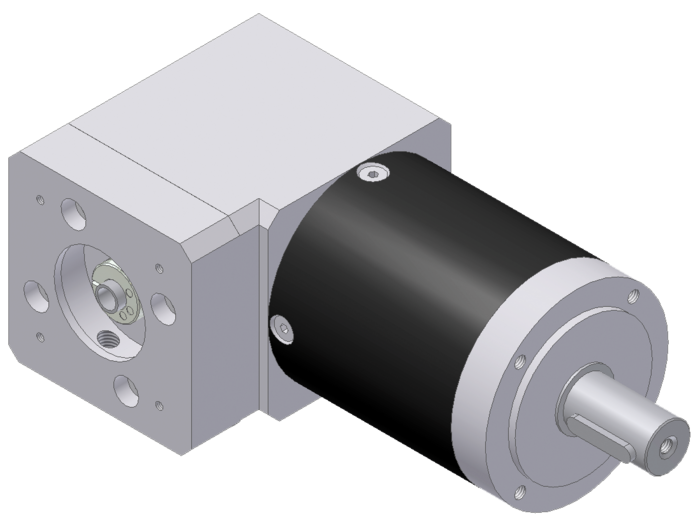

Angular Planetary gear WPLE 80 – Permanent Operation / Periodic Duty up to 130 / 208 Nm

The WPLE 80 is the 90° angle version to the PLE 80. The motor and gear are connected with a detachable coupling and clamping hub. Friction losses cannot be neglected. A bevel gear 1:1 is in front of the PLE 80. The gear backlash increases by an angle part of 6 arcmin.

Features

- 22 different gear ratios, i = (3 … 512)

- low backlash (15-19-21 arcmin), (1-2-3)-stage

- high level of efficiency (94-92-88 %), (1-2-3)-stage

- high admissable shaft forces, 1.200 … 950 N, axial-radial

- no axial offset shaft output

- high short term overload factor 1,60

- arbitrary mounting position

- lifetime lubrication

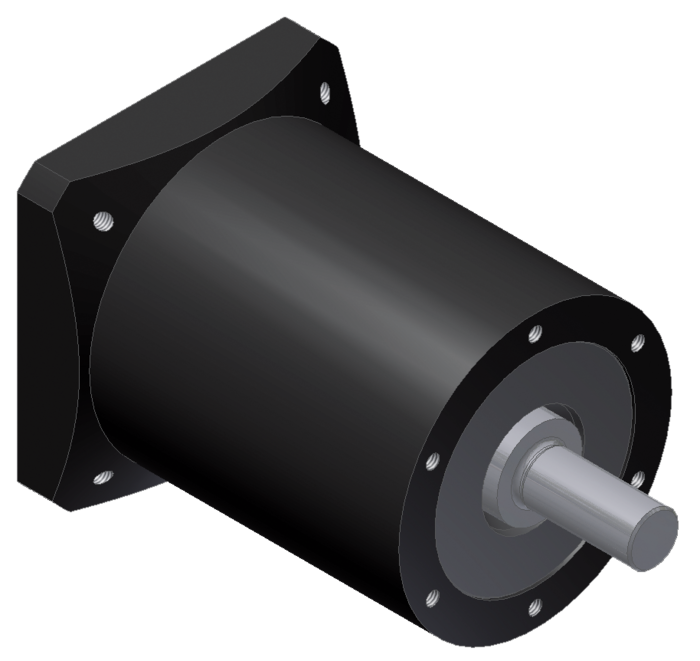

Harmonic-Drive-Gear HFUC-14 – Permanent Operation / Periodic Duty up to 7,8 / 28 Nm

The HFUC-14 is a backlash free precision gear. Angular tolerances are determined by the torsional stiffness. The motor and gear are non-detachable and connected to one another. The efficiency is strongly load-dependent. The gear is ideal for applications where a backlash of a servo gear is insufficient.

Features

- 4 different gear ratios, i = (30 … 100)

- backlash-free

- high load-dependent level of efficiency

- high admissable radial force 1.500 N

- coaxial shaft output

- high short term overload factor approximately 2

- arbitrary mounting position

- lifetime lubrication