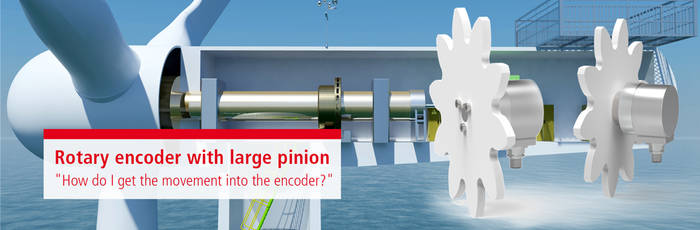

Rotary encoder with large pinion

The question arises again and again: “How do I get the movement into the encoder?”

For rotary encoders that monitor pitch adjustment in wind turbines, pinions that engage directly in the pitch adjustment gear rim have proven the preferred solution. This monitors the movement “at the end” of the drive train and thus records the entire chain from the motor to the gearbox to the sprocket. High-quality plastics are used for the pinion that transmits the rotary motion of the sprocket to the encoder shaft in a wear-free and mechanically reliable manner.

By adjusting the angle of attack of the rotor blades (“pitch”), the wind turbine is adapted to the various wind speeds. In order to achieve optimal energy generation even in gusty winds, the angle of attack is continuously regulated. The pitch adjustment also plays an important role in maintaining the operating conditions – by leaving the optimum angle of attack, the system can be gently braked even in windy conditions before the mechanical brakes kick in.

The nacelle of the wind turbine is aligned according to the wind direction. The nacelle position must be measured absolutely over several revolutions. The connecting lines between the nacelle and the foundation do not allow endless rotation in one direction. As with pitch adjustment, azimuth tracking is also used to bring the system into a safe state.

For this application, TR-Electronic now offers encoders directly with a pre-assembled drive pinion. The required pinion can be adapted to the requirements in terms of module and number of teeth.

The CMV582M-SSI rotary encoders with pre-assembled pinions are equipped with robust bearing mechanism to cope with the harsh conditions in a wind turbine. This means that the encoder is an “install and rely on” component even if modern wind turbines have an extended service life – like all sensor systems that were developed by TR-Electronic for permanent use even in harsh environments.